Our innovative run-of-river design ensures minimal environmental impact while efficiently generating power.

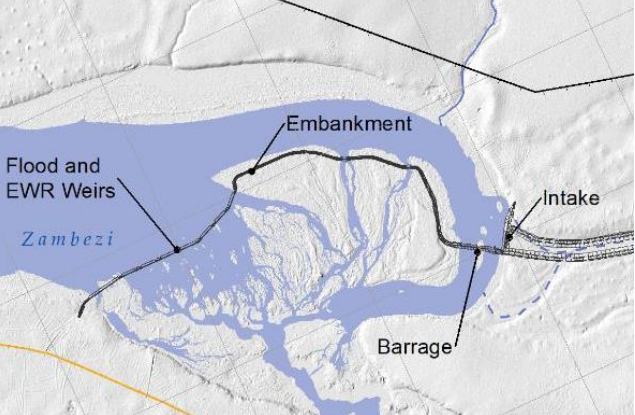

Our innovative headworks system is a marvel of engineering, designed to ensure optimal performance and environmental harmony. Here’s how it works:

By diverting a portion of the river’s flow through our intake structure and into the power canal, we harness the river’s energy efficiently and sustainably.

Our headworks on the west (right) river channel are designed with both efficiency and environmental care in mind.

By integrating these features, we harness the river’s power while preserving its natural beauty and ecological health.

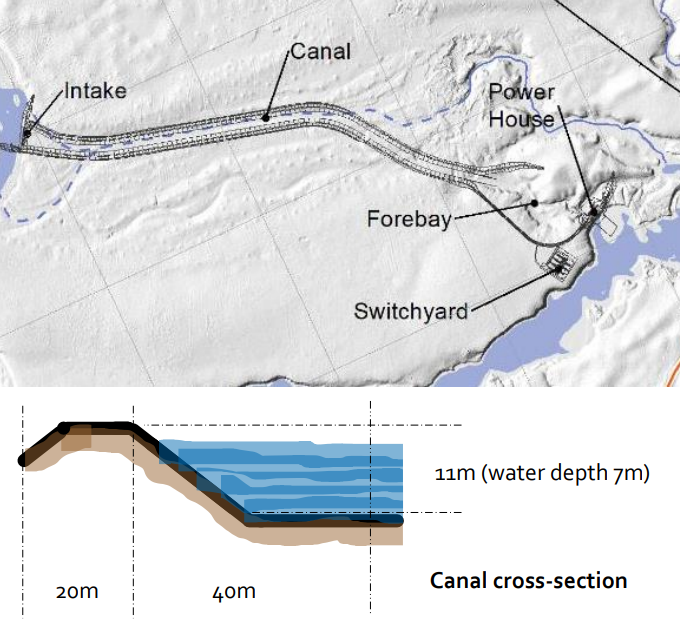

Our power canal is a key component in our energy generation process.

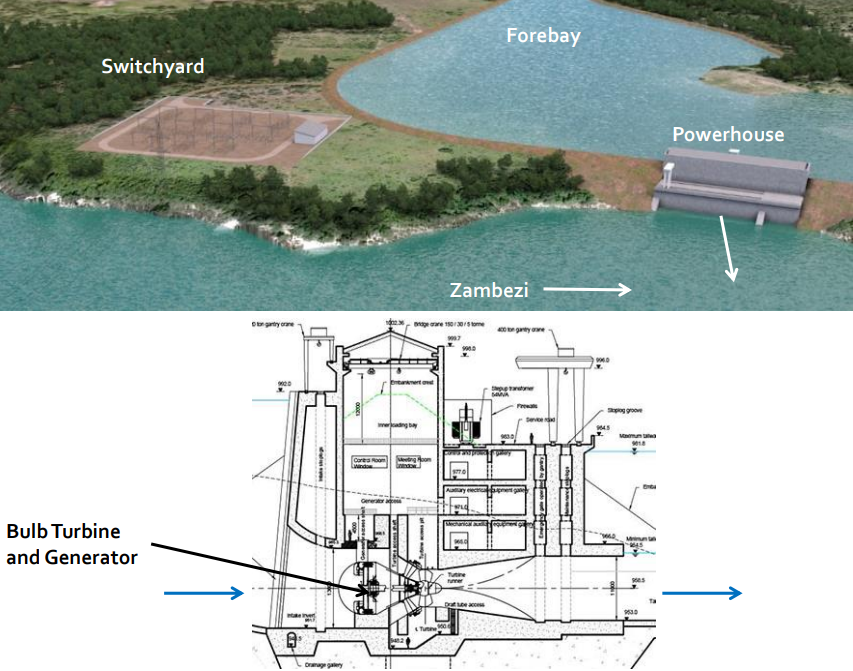

Our powerhouse is the heart of our energy generation, featuring the below technology and design:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.